XS Sight Systems Factory Tour

XS Sight Systems Factory Tour

I recently had the awesome opportunity to join the crew from RSKTKR for a personal factory tour of XS Sight Systems. Led by Justin Springer, who was also an RSO for our RSKTKR Combative Handgun class, we had the chance to learn all about XS and how they operate.

If you’re not familiar with XS Sight Systems, I’d urge you to take a look at their Website to find out about all the benefits and fast sight acquisition that they give you. I’ve recently installed a set of Big Dot 24/7 sights on my Sig P226, and am very pleased with their performance.

I’ll have a full write up of my experience with the sights thus far, so look for that soon. Let’s get on with the tour!

Facility

The first thing I noticed about the XS building was how nondescript it was. You’d never believe that behind the brick facade lies the manufacturing of quality weapons sights used the world over.

The first thing I noticed about the XS building was how nondescript it was. You’d never believe that behind the brick facade lies the manufacturing of quality weapons sights used the world over.

Their building is definitely not set up as a retail walk-in facility, but they welcome customers in anytime. As Justin showed us in, we met a few of the members of their staff including the mustachioed Bo Wallace, Gunsmith extraordinaire and head of tech support for XS. You may know who I’m talking about if you’ve ever viewed any of the XS Installation videos on YouTube.

What immediately impressed me, as we worked our way back over to Justin’s desk, was the wall of inventory that XS keeps. I had no idea that they had so many parts to stock! I’ve always known they made sights for a wide range of guns, but to see them all in the individual containers was impressive. XS keeps an inventory of hundreds of unique parts and sights.

Unbeknown to most, is that XS Sight Systems makes more than just sights. Their large production operation and facility also produces equipment for the medical industry, as well as the oil & gas industry. This important detail helps keep their machining costs low, which in turn keeps the price of their sights down.

Production

After Justin spoke to us about the inventory they keep and a few of the company details, we met up with their lead machinist Matthew.

After Justin spoke to us about the inventory they keep and a few of the company details, we met up with their lead machinist Matthew.

Matthew started with showing us three stages of the sight production process (machined, anodized and blued) and explained how almost every step in the production of their sights is done in-house, with the exception of anodizing, bluing and inserting the tritium. Anodizing and bluing are done locally which dramatically decreases production time.

The Tritium inserts, while installed at Trijicon in Michigan, are turned around very quickly. Justin mentioned how accommodating they were on rush jobs if needed.

Raw Material

All XS Sights start their life as either 1 1/16″, 3/4″ or 5/8″ raw bar stock, which is then cut into smaller bars of a specified length and loaded into a CNC Machine.

All XS Sights start their life as either 1 1/16″, 3/4″ or 5/8″ raw bar stock, which is then cut into smaller bars of a specified length and loaded into a CNC Machine.

XS has multiple CNC machines, the vast majority being CNC Mills, though they do have CNC Lathes that are used for certain items. Most day-to-day production is done on five Brother CNC Mills located in the main XS building. Behind the main building is another machine shop, where most of their medical and oil & gas machining is done, but it’s also used for parts that require a second operation. All XS scope rails are completely run in the back shop.

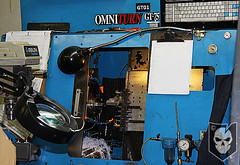

The PVC dots for their sights are run on an Omniturn CNC lathe that is probably older than most people reading this article, but is still around because it runs like a champ.

The PVC dots for their sights are run on an Omniturn CNC lathe that is probably older than most people reading this article, but is still around because it runs like a champ.

Production is fueled by demand and there are some sights that don’t move as fast off the shelves as others, those may only be manufactured once a year or as needed. Needless to say that their machines are always running, as there’s no shortage of demand for these sights in the more popular guns.

Process

Once the appropriately sized bar stock is cut to the necessary length, it’s fed into the CNC Machine and cut to the desired sight size. From there the sight is hand deburred and ready for outside finishing (anodizing and bluing). From there the sights are sent to Trijicon for Tritium if required.

Once the appropriately sized bar stock is cut to the necessary length, it’s fed into the CNC Machine and cut to the desired sight size. From there the sight is hand deburred and ready for outside finishing (anodizing and bluing). From there the sights are sent to Trijicon for Tritium if required.

After returning to XS, the sights are hand painted, packaged and shipped out from their Ft. Worth, Texas facilities.

Closing Notes

It was very impressive to get a personal tour of XS Sight Systems and to meet the friendly and knowledgeable staff behind the company. The amount of skill and attention to detail that goes into each and every step of the production process was fascinating to say the least.

It was very impressive to get a personal tour of XS Sight Systems and to meet the friendly and knowledgeable staff behind the company. The amount of skill and attention to detail that goes into each and every step of the production process was fascinating to say the least.

I’d urge anyone in the area to stop by and say hi to Justin, or give him a call. He knows his stuff and is more than willing to answer any questions you might have about XS Sights for your gun.

In fact, i’d bet that if you left a question here, he’d personally answer it if we can’t. He’s been known to loiter on ITS…

Thanks again to Justin and the entire staff of XS Sight Systems for taking time out of their day to show a few gun bums around the shop!

[flickrset id=”72157623812746873″ thumbnail=”square” overlay=”true” size=”medium”]

Discussion