Military Ammunition Failures and Solutions

Military Ammunition Failures and Solutions

Today we bring you another fascinating article written by Dr. Gary K. Roberts, who we have covered extensively here on ITS in regards to his body armor testing.

Today we bring you another fascinating article written by Dr. Gary K. Roberts, who we have covered extensively here on ITS in regards to his body armor testing.

The article we bring you today is a transcription of a talk Roberts gave to the National Defense Industrial Association (NDIA) entitled “Time for a Change.”

For those of you not familiar with Dr. Roberts, please read the following bio from our previous article. Dr. Roberts was an independent researcher on the most recent FBI Body Armor Test Protocol.

We’d like to thank Dr. Roberts for giving us permission to repost this information here for our readers.

Time for a Change

Military Small Arms Ammunition Failures and Solutions

- Training…and More Training

- Reliable and Durable Weapon System

- Ammunition Terminal Performance

The first two items must be fully and adequately addressed before the third item becomes a serious concern…

What’s Wrong With This Picture?

In 1940, the prototype P51 Mustang successfully flew just 178 days after the initial order had been placed. Now in the 21st century, despite the efforts of many smart folks, few small arms improvements seem to get rapidly completed and expediently fielded–there is a significant gap between what we KNOW and what we actually DO for our warriors. If such glacial procurement had occurred during WWII, the war would have ended before any new weapons were fielded.

SALVO, SPIW, 6 mm SAW, ACR, XM29, XM8…even with modern engineering, CAD/CAM techniques, and new materials many proposed U.S. small arms and ammunition improvements cost tens of millions of dollars, years of RDT&E, and then rarely seem to ever actually reach the field.

Millions of dollars are poured into next generation small arms technologies with no near-term potential to improve combat capability, like caseless, telescoping, snd air-burst ammo, while simple innovative incremental advances that can immediately make an impact in combat operations, like barrier blind ammunition and intermediate calibers, get minimal funding or are ignored.

DOD replaces computer hardware and software every 3 or 4 years, yet does not offer the same type of incremental improvements for small arms weapons and ammunition, despite similar costs.

The sacred alter of “green” ammo has sucked up tens of millions of dollars over many years in the nebulous pursuit of “non-toxic” ammunition, yet with a few COTS exceptions, has not resulted in any improvements in ammunition reliability, accuracy, or terminal performance–the factors that actually help win fights.

Overly complex, fundamentally flawed computer modeling and excessive statistical manipulations that don’t reflect reality are often used to try and predict military ammunition terminal performance and “lethality” instead of the more common sense approach using the physiological damage based methodology proven to closely correlate with numerous actual shooting incidents in over two decades use by law enforcement agencies and wound ballistic researchers.

Ideal Caliber?

The United States made several major missteps in its search for the ideal combat rifle caliber. In the late 1920’s, the U.S. Army selected the .276 Pederson caliber produced by Frankford Arsenal as the best caliber for a new semi-automatic rifle. The .276 fired a 125 gr bullet at approximately 2700 f/s. Ordnance trials determined that John Garand’s new .276 caliber T3E2 rifle was an ideal combat weapon, however, development of the .276 rifle was halted in 1932 because of the largeremaining stocks of old .30-06 caliber M1906 150 gr FMJ ammunition left over from WWI; thus the U.S. military threw away an opportunity to adopt the superior performing .276 caliber and theM1 Garand rifle was adopted in the old .30-06 caliber.

Following WWII the United States Army again made a colossal weapon system selection error when it rejected the British .270 caliber 130 gr and .280 caliber 140 gr ammunition fired at approximately 2400 f/s and instead insisted on the full power 7.62 x 51 mm cartridge that offered nearly identical ballistic characteristics as the old .30-06 it replaced. Given the 7.62 mm’s extremely short life as the standard service rifle caliber, in hindsight, we can hypothesize that both the .270 (6.8 mm) and .280 (7 mm) would probably have been ideal combat rifle calibers and might still be in use today if either had been chosen.

In 1972, the U.S. Army issued a MNS and detailed specifications for a new SAW/LMG. At that time, in reviewing calibers for the new system, 5.56 x 45 mm was felt to lack effective range and terminal performance while 7.62 x 51 mm was felt to be too heavy; weapon developers and joint users felt no current weapons systems and calibers could meet the requirements, thus a new compromise caliber was necessary–this became the 6 x 45 mm SAW. The 6 mm SAW used a 105 gr low drag bullet fired at around 2450 fps. In 1976, the Army ordered that SAW design efforts be redirected, this included stopping development of the 6 mm SAW cartridge (in part for fear of irritating our NATO allies) and focusing efforts on 5.56 mm LMG designs (XM248/(XM235), XM249/(FN Minimi), XM262/(HK21A-1).

While 5.56 mm 55 gr M193 (FN SS92) was standard in the 1960’s and 1970’s, attempts to improve 5.56 mm effectiveness included the XM287 68 gr FMJ and the IWK 77 gr FMJ–both used in the Stoner 63 by NSW in Viet Nam; the 54 gr XM777, as well as the SS109 62 gr FMJ developed by FN for their Minimi LMG. As we all know, the end result was the 1980 decision to adopt the 5.56 mm Minimi as the M249 SAW and the SS109 as the 62 gr FMJ M855 “green-tip.”

As noted, 5.56 mm NATO 62 gr SS-109/M855 FMJ was designed over 30 years ago as linked machine gun ammunition to be fired from the FN Minimi/M249 SAW while engaging enemy troops wearing light body armor during conventional infantry combat at distances of several hundred meters–while not a perfect solution, M855 does perform adequately in this role.

Terminal Performance Problems

Unfortunately, combat operations since late 2001 have again highlighted terminal performance problems, generally manifested as failures to rapidly incapacitate opponents, during combat engagements when M855 62 gr “Green Tip” FMJ is fired from 5.56 mm rifles and carbines. This is not surprising, since M855 was not originally intended for use in carbines or rifles, especially those with short barrels.

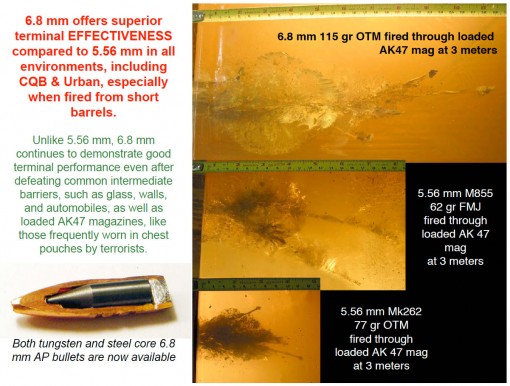

In addition, most 5.56 mm bullets are generally less effective when intermediate barriers, such as walls, glass, and vehicles shield opponents–this is a significant consideration in urban combat. The decreased incapacitation potential of 5.56 mm compared with larger rifle calibers is intrinsic to the small caliber varmint hunting roots of the 5.56 mm cartridge; in many states it is illegal to hunt deer size game with 5.56 mm, so why do we expect it to offer ideal terminal performance against aggressive, violent 100-200 lbs human opponents?

As an interim solution to these problems, deployed SOF units have used 5.56 mm Mk262. The Black Hills produced Mk262 uses the 77 gr Sierra Match King (SMK) OTM and is built as premium quality ammunition intended for precise long-range semi-auto rifle shots from the Mk12 rifle. It is great for its intended purpose. Mk262 has demonstrated improved accuracy, greater effective range, and more consistent performance at all distances compared to M855 when fired from current M16, Mk12, M4, HK416, and Mk18 rifles and carbines. However, despite this substantially improved performance, Mk262 still manifests the problems of poor intermediate barrier penetration and somewhat variable terminal performance inherent with the SMK design.

The disturbing failure of 5.56 mm to consistently offer adequate incapacitation has been known for nearly 15 years. Dr. Fackler’s seminal work at the Letterman Army Institute of Research Wound Ballistic Laboratory during the 1980’s illuminated the yaw and fragmentation mechanism by which 5.56 mm FMJ bullets create wounds in tissue. If 5.56 mm bullets fail to upset (yaw, fragment, or deform) within tissue, the results are relatively insignificant wounds, similar to those produced by .22 LR–this is true for ALL 5.56 mm bullets, including military FMJ , OTM, and AP, as well as JHP and JSP designs used in LE.

The disturbing failure of 5.56 mm to consistently offer adequate incapacitation has been known for nearly 15 years. Dr. Fackler’s seminal work at the Letterman Army Institute of Research Wound Ballistic Laboratory during the 1980’s illuminated the yaw and fragmentation mechanism by which 5.56 mm FMJ bullets create wounds in tissue. If 5.56 mm bullets fail to upset (yaw, fragment, or deform) within tissue, the results are relatively insignificant wounds, similar to those produced by .22 LR–this is true for ALL 5.56 mm bullets, including military FMJ , OTM, and AP, as well as JHP and JSP designs used in LE.

This failure of 5.56 mm bullets to upset can be caused by reduced impact velocities when hitting targets at longer ranges, as well as by the decreased muzzle velocity when using short barrel carbines. Failure to upset can also occur when bullets pass through minimal tissue, such as a limb or the torso of a thin, small statured individual, as the bullet may exit the body before it has a chance to upset. Finally, bullet design and construction plays a major role in reliable bullet upset. Without consistent bullet upset, wounding effects are decreased, rapid incapacitation is unlikely, and enemy combatants may continue to pose a threat to friendly forces and innocent civilians.

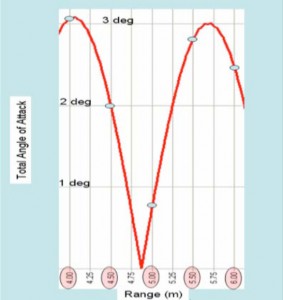

Angle-of-Attack

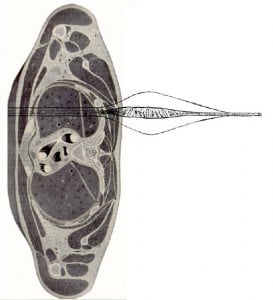

Angle-of-Attack (AOA) variations between different projectiles, even within the same lot of ammo, as well as Fleet Yaw variations between different rifles, were recently elucidated by the JSWB-IPT. These yaw issues were most noticeable at close ranges and were more prevalent with certain calibers and bullet styles–the most susceptible being 5.56 mm FMJ ammunition like M855 and M193.

Angle-of-Attack (AOA) variations between different projectiles, even within the same lot of ammo, as well as Fleet Yaw variations between different rifles, were recently elucidated by the JSWB-IPT. These yaw issues were most noticeable at close ranges and were more prevalent with certain calibers and bullet styles–the most susceptible being 5.56 mm FMJ ammunition like M855 and M193.

What this means is that two shooters firing the same lot of M855 from their M4’s with identical shot placement can have dramatically different terminal performance results: one shooter states that his M855 is working great and is effective at dropping bad guys, while the other complains his opponents are not being incapacitated because M855 is zipping right through the targets without upsetting. Both shooters are telling the truth…

Improvement Needed

As articulated by combat AAR’s the last few years and demonstrated in recent military wound ballistic testing, improved combat ammunition that is specifically designed for rifle and carbine use, not machine guns, is urgently needed.

New loads should offer:

- JAG approval

- Full reliability in diverse environmental extremes

- A thermally stable propellant

- Consistent lot-to-lot and shot-to-shot performance, even when fired from short barrel weapons

- Crimped and sealed primer

- Sealed case mouth

- Cannelure for functional reliability in adverse conditions

- Decreased muzzle flash

- Acceptable accuracy at 300-500m

- Good soft tissue terminal performance (early consistent bullet upset within 1 or 2 inches of initial tissue penetration)

- 12-18 inches of penetration coupled with maximized tissue damage during the first 10 to 12 inches of travel in tissue

- Designed to minimize AOA and fleet yaw issues

- Blind to Barriers

It is critical that new combat ammunition be “Blind to Barriers” and not suffer from terminal performance degradation from intermediate barriers–especially automobile windshields & doors, and common structural walls.

Ammunition should be light and compact enough for the operator to carry an adequate supply in magazines of at least a 25 round capacity. The rifle should be similar in size, weight, and ergonomics to the proven M4/M16 weapons. Recoil should be manageable to allow full auto fire when necessary, along with the more usual rapid, aimed semi-automatic fire.

Important Gel Block Measurements to Assess Terminal Effectiveness

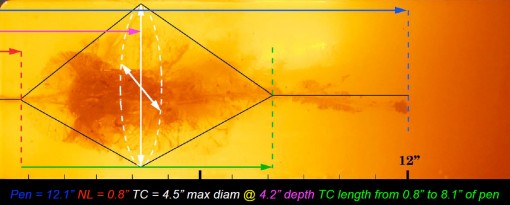

The shot into bare gelatin depicted below illustrates ideal terminal performance.

“Barrier Blind” ammunition should demonstrate minimal changes in terminal performance between unobstructed shots into bare gelatin and those obstructed by intermediate barriers.

- Initial Upset Depth (Neck Length) — Optimally 1” or less, up to 3”

- Temp Cavity Length — As long as possible in the first 12” of penetration

- Temp Cavity Height & Width — Bigger is better in first 12” of penetration

- Depth to Max Temp Cavity Diameter — Typically at 4” to 6” of pen

- Total Depth of Penetration — Less than 12” & more than 18” is not ideal

Note: The ideal shot depicted above is a 6.8 mm Hornady 115 gr OTM impacting at 2600 fps

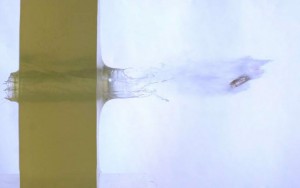

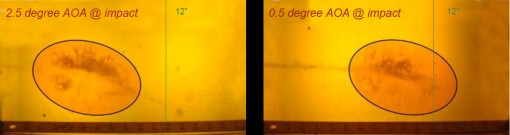

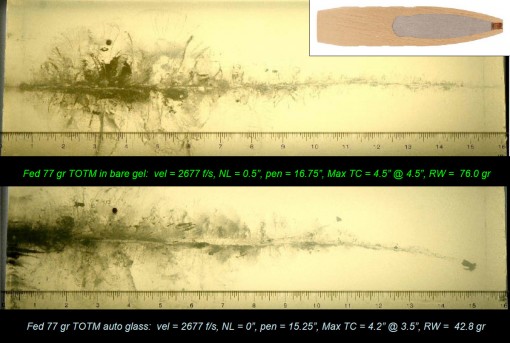

Tom Burczynski’s superb photos of 5.56 mm projectiles as they penetrate through 2” wide sections of 10% gelatin clearly illustrate the critical importance of early projectile upset within the first 1 or 2” of penetration.

Tom Burczynski’s superb photos of 5.56 mm projectiles as they penetrate through 2” wide sections of 10% gelatin clearly illustrate the critical importance of early projectile upset within the first 1 or 2” of penetration.

The barrier blind, FBI issued, ATK/Federal 62 gr bonded Tactical load on top has completely upset within the first 2” of gel penetration, demonstrating good tissue crush and stretch.

In contrast, the Mk262 loading using the 77 gr SMK OTM on the bottom has not even begun to upset during the first 2” of penetration through gel, resulting in minimal tissue stretch and crush at this point.

In contrast, the Mk262 loading using the 77 gr SMK OTM on the bottom has not even begun to upset during the first 2” of penetration through gel, resulting in minimal tissue stretch and crush at this point.

5.56 mm BOTTOM LINE

Simply adopting new 5.56 mm barrier blind combat loads that are optimized for shorter barrels, offer consistent early upset, along with adequate penetration, and minimal AOA/Fleet yaw issues may be the critical answer to many deficiencies noted with currently issued U.S. military 5.56 mm ammunition.

“In response to inquiries from the field, the Army’s Project Manager, Maneuver Ammunition Systems (PM MAS) has assembled a team of experts from many disciplines including military users, law enforcement, trauma surgeons, aero ballisticians, weapon and munitions engineers, and other scientific specialists to answer the question–Are there Commercial Off-the-Shelf 5.56mm bullets available that are better than M855 “Green Tip” against unarmored targets in Close Quarters Battle (CQB)?”

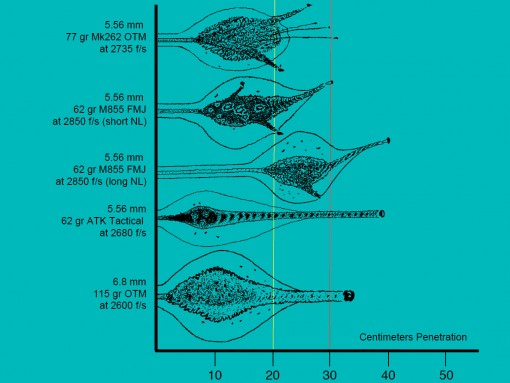

Despite what was publicly released in the heavily truncated “final” JSWB-IPT report from May 2006, as well as the information presented in Infantry Magazine that was replete with significant data omissions, anybody who has seen the actual data from the 10,000 or so test shots collected by the JSWB-IPT at 3-10m, 100m, and 300m distances or who has read the original 331 page final draft report dated 12 April 2006, knows that the clear and unequivocal best performing cartridge in the JSWB-IPT testing was 6.8 mm.

In addition, several 5.56 mm loads performed better than current M855, especially from shorter barrels. This was validated by the 11 August 2006 joint USMC/FBI Phase I Ammunition Study report that once again clearly illustrated that 6.8 mm offered the best terminal performance of ALL calibers tested. The report also demonstrated that the 5.56 mm 62 gr “Barrier Blind” load used by the FBI and other LE agencies offered superior terminal performance to current military issue 5.56 mm ammunition.

The JSWB-IPT wrote:

- “The best performing systems emphasizing tissue damage, on the average, in this study were of larger caliber than 5.56 mm.”

- “The 6.8 mm performance observed in this test suggests that an intermediate caliber is the answer to the trade-off balance issue.”

- “The 6.8 mm projectile had a near optimal balance of MASS, VELOCITY, and CONFIGURATION to maintain its effectiveness, even at a lower impact velocity.”

- “The 6.8mm SPC is far and above, the best performing ammunition…”

Thus, the Road Ahead for Military Small Arms Ammunition should emphasize: “Barrier Blind” ammunition in all calibers, calibers larger than 5.56 mm, especially intermediate calibers like 6.8 mm.

Special Purpose Cartridge Program

The SPC (Special Purpose Cartridge) program, jointly developed by 5th SFG(A) and USAMU in conjunction with USSOCOM requirement validation, built on historical data in creating the 6.8 x 43 mm SPC. 6.8 mm is the perfect refinement of the hypothesis that a 6.5 to 7 mm bullet is the ideal choice for combat; it combines the best features of both the more traditional 7.62 x 51 mm “battle rifle” cartridge and the more recent 5.56 x 45 mm “assault rifle” cartridge without either of their deficits.

In addition, 6.8 mm offers superior accuracy and incapacitation potential compared to the 7.62 x 39 mm cartridge fired by AK47 rifles commonly used by our opponents. Unlike 5.56 mm NATO and 7.62 mm NATO weapons, 6.8 mm was designed from the beginning to offer optimal performance in the sub-16” short barreled carbines favored by U.S. forces fighting in urban settings and from vehicles.

6.8 mm was conceived and developed entirely by experienced military end-users based on identified combat mission needs. Their Commanders approved the project, trusted the competence of their subordinates, and supported them in developing the best solution for troops at the tip of the proverbial spear. This was a bottom-up project where the personnel who will have to use the weapon in combat for once got to develop exactly what they needed, rather than the more common top-down approach where engineers develop a product that is all too often long-delayed and that does not necessarily adequately address the needs of combat personnel in the field. The 6.8 mm SPC project was also very inexpensive–in an era of massive fiscal waste, the 6.8 mm SPC initial RDT&E costs for the government were less than $5000.

During SPC development different bullet diameters of 6 mm, 6.5 mm, 6.8 mm, 7 mm, and 7.62 mm were tested, using multiple bullet types, shapes, and weights from 90 to 140 gr–the 6.8 mm was selected because it offered the BEST combination of combat accuracy, reliability, and terminal performance for 0-500 yard engagements in an M4 size package.

During SPC development different bullet diameters of 6 mm, 6.5 mm, 6.8 mm, 7 mm, and 7.62 mm were tested, using multiple bullet types, shapes, and weights from 90 to 140 gr–the 6.8 mm was selected because it offered the BEST combination of combat accuracy, reliability, and terminal performance for 0-500 yard engagements in an M4 size package.

MURG Evaluation

Based on all available test results to date, end-users selected 6.8 mm as the best available intermediate caliber for the TSWG multi-agency task force MURG evaluation.

Three different MURG variants were required:

- Special Compact Carbine with 8-10” barrel (SCC = Mk18 equivalent)

- Standard Carbine with 12-14” barrel (SC = M4 equivalent)

- Designated Marksman-Recce with 16-18” barrel (DMR = Mk12 equivalent)

6.8 mm MURG systems from four vendors were tested: Barrett, Bushmaster, HK, LWRC, with the 5.56 mm Colt M4A1 as baseline.

Test Conclusions Include:

- 6.8 mm MURG is a COTS NDI item ready for full fielding in the next 12 months

- 6.8 mm MURG is fully compatible with existing M4A1 and M16 lower receivers

- 6.8 mm MURG allows end-user to change between variants in the field within seconds

- NO parts failures occurred in any 6.8 mm MURG system during testing

- 6.8 mm MURG systems exhibited accuracy, reliability, suppressor capability, recoil management, and engagement speed that were equivalent or better than current 5.56 mm weapons

- 6.8 mm MURG is available as a gas piston/op rod system for improved durability, reliability, and reduced user maintenance

- 6.8 mm MURG should be treated as an integrated system–upper, magazines, suppressor, and ammunition to ensure maximum reliability

MURG allows units to train with 5.56 mm uppers currently in service and fight with identically configured 6.8 mm uppers, as the “muscle memory”, weapons handling skills, and LBE are identical.

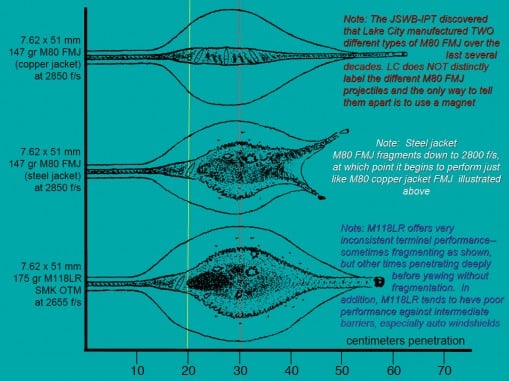

7.62 x 51 mm

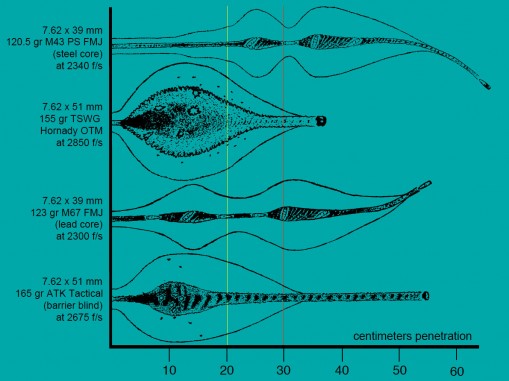

To alleviate the problems of marginal incapacitation potential and intermediate barrier penetration ability inherent with 5.56 mm, re-adoption of a 7.62 x 51 mm length cartridge is a consideration (ex. 7.62 x 51 mm, 7 x 46 mm, 6.5 mm Creedmore). The superior range, incapacitation potential, & barrier penetration ability of 7.62 x 51 mm based systems may prove a decisive advantage compared to smaller caliber weapon systems, however ammunition with terminal performance far SUPERIOR to currently issued M80 ball is MANDATORY to optimize the potential of 7.62 mm rifles for CQB and urban combat!

Neither type of current 7.62 mm M80 FMJ possesses ideal accuracy or terminal performance characteristics, especially from barrels shorter than 16-18”. 7.62 mm M118LR 175 gr OTM used in sniper rifles like the Mk11, M110, M24, and M40A3 is very accurate and offers good performance at longer ranges–making it ideal for sniper use. However, the documented inconsistent close range terminal performance and poor intermediate barrier performance of the heavy SMK OTM make it a less than ideal choice for CQB engagements, urban combat, and short barrel use. Improved ammunition is required to optimize terminal performance with shorter barrel 7.62 x 51 mm weapons (Mk14/M14 EBR, KAC SR25K, HK417, FN Mk17 SCAR-H).

Despite the many desirable characteristics of 7.62 x 51 mm based systems, they have several significant penalties, including increased cost, size, weight, and recoil, as well as decreased magazine capacity and decreased control in full auto fire. The basic ammo load is reduced and the soldier’s overall load is increased. Short barrel 7.62 x 51 mm weapons have substantial muzzle flash and blast, along with reduced terminal performance. 7.62 mm magazines require different size pouches than current M4/M16 LBE. In addition, several recent 7.62 mm weapon systems have not proven reliable or durable when subjected to combat conditions.

How Can the U.S. Military Field More Effective Ammunition?

The most expeditious solution to improve terminal performance for current 5.56 mm carbines is to abandon M855 and adopt a consistent performing “Barrier Blind” combat load specifically designed for carbine use as the standard issue U.S. military 5.56 mm ammunition.

The most expeditious solution to improve terminal performance for current 5.56 mm carbines is to abandon M855 and adopt a consistent performing “Barrier Blind” combat load specifically designed for carbine use as the standard issue U.S. military 5.56 mm ammunition.

The ideal answer to upgrade current weapons and the clear choice for any new assault rifle is to adopt an intermediate caliber like the 6.8 mm, as this has proven to be the most efficient & effective choice in weapons with barrels 16” and shorter.

The final alternative is to field an improved 7.62 mm based system although for this to be of benefit, ammunition with performance dramatically superior to M80 ball, such as the TSWG 155 gr OTM or preferably, a new barrier blind load, needs to be standard issue.

NOTE: Current M995/M993 AP availability is too limited, especially for rifle and carbine use. It is critical to ensure that effective AP ammo is readily available on stripper clips for use in carbines & rifles, for ALL personnel potentially engaging in combat, just like GI’s had available for their M1 Garands and BAR’s in WWII. Abundant AP ammo availability may prove critical in potential future conflicts against modern, well equipped opponents wearing advanced body armor.

1899 Hague Convention

More than 100 years later, it may be time for Congress and the President to re-evaluate the outmoded and archaic 1899 Hague Convention’s prohibition against routine combat use of the standard deforming ammunition commonly used by LE personnel. The Hague Convention’s guidelines are no longer relevant for today’s urban battlefield with its close intermixing of innocent civilians and irregular combatants.

The U.S. is not a party to the 1899 Hague treaty, but has complied with it in international armed conflict; as a result, the majority of U.S. military personnel are limited to using FMJ ammunition in combat. It is patently ludicrous to conclude that incapacitating dangerous opponents in combat while using the same deforming bullets legally relied on daily by LE agencies is somehow inhumane and unlawful, while wounding or killing the same enemy using much more powerful destructive ordnance such as grenades, mines, mortars, artillery, rockets, bombs, CBU’s, FAE’s, and thermobarics is approved and condoned. This is neither logical nor just and in fact does nothing to limit the severity of battlefield casualties.

In many respects, the use of deforming LE type ammunition during modern combat is far more humane, as accurate and effective ammunition reduces the need for multiple shots–decreasing the chance of shots missing the intended opponent and striking innocent civilians. Deforming projectiles also mitigate the potential of innocent bystanders getting hit by bullets which first perforate the target They may also reduce the number of times a dangerous opponent must be shot, potentially limiting the amount of surgical intervention needed to control hemorrhage.

It is time to move beyond the illogical prohibitions regarding modern deforming small arms projectiles in the antiquated 1899 Hague Convention and authorize all U.S. military personnel to routinely field the same deforming ammunition used daily by American LE officers, as it has consistently proven to be efficacious in rapidly stopping hostile actions by violent opponents and highly effective at protecting both friendly forces and innocent civilians.

The .pdf of the article is available here

Discussion